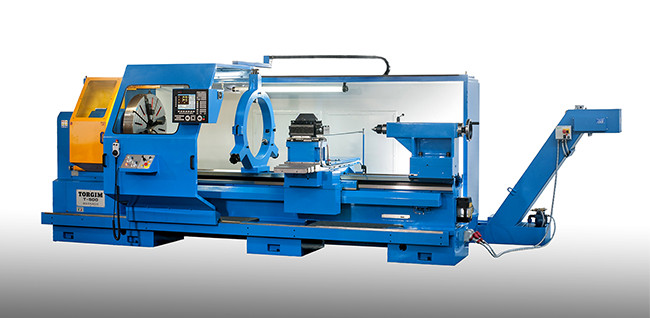

This lathes range has for standard an automatic speed gear range, 30 Kw spindle motor and a swarfs conveyor. It’a a machine for high cutting depth, it’s a perfect one to work forged pieces and very hard materials.

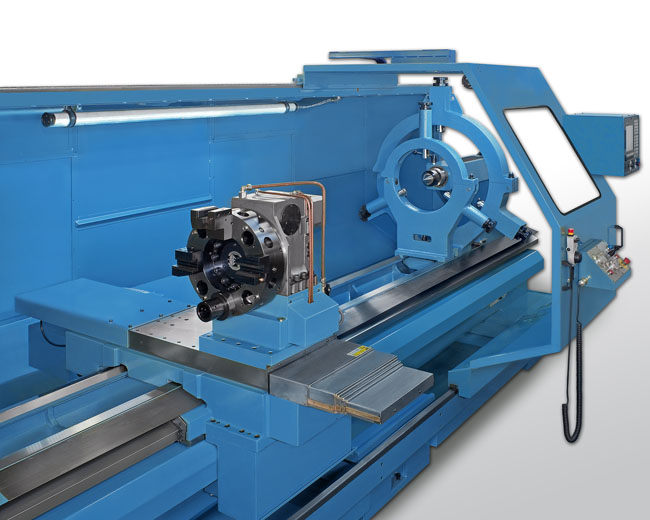

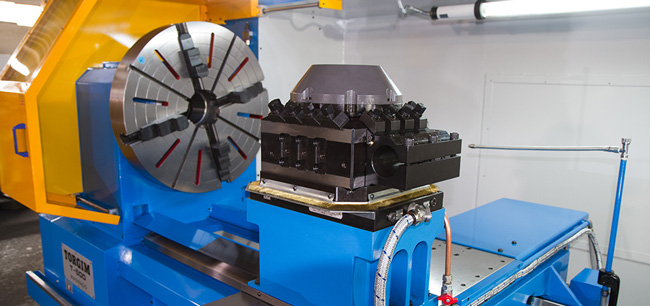

Headstock: The head, melted in special stabilized Meehanite cast-iron, is steadily fixed on the bed and it is free from vibrations. All gears are made of Cr.Ni.Mo. steel, hardened and ground; the ones that transmit the motion to the spindle have helical involute profile. The spindle, provided with hole Ø 160 mm, is supported in three points and is mounted on precision TIMKEN ball bearings. The machine is with automatic speed gear range by means of an hydraulic piston and relative unit, an heat exchanger assures constant temperature inside the head.

Carriage: The carriage slides on the bed guided in the front part by a prismatic guide and in the back part by a flat guide. With a solid structure it is able to stand to a strong cutting moment assuring a constant precision at the same time. The transversal slide has a support section very wide that gives it sturdiness. The ways of the cross slide are ground and adjusted by means of conic gibs: the ways between the movable parts are covered by TURCITE to allow motion regularity also at lowest feeds and are manually scrape-finished so to guarantee an accurate assembly. The movements are driven by high precision recirculating ball screws.

Bed: The bed, melted in special Meehanite cast-iron and covered on all the length, is carried out with a double-walled structure, to assure the highest stiffness, in the worst duty conditions too. The natural gap under the head increases the machining potentialities allowing to work very large flanges usually workable on lathes much more bulky.

Data:

- Spindle power 30 kW

- Spindle bore 160 mm

- Tailstock sleeve diemeter 120 mm

- Distance between centers 2000-5000 mm