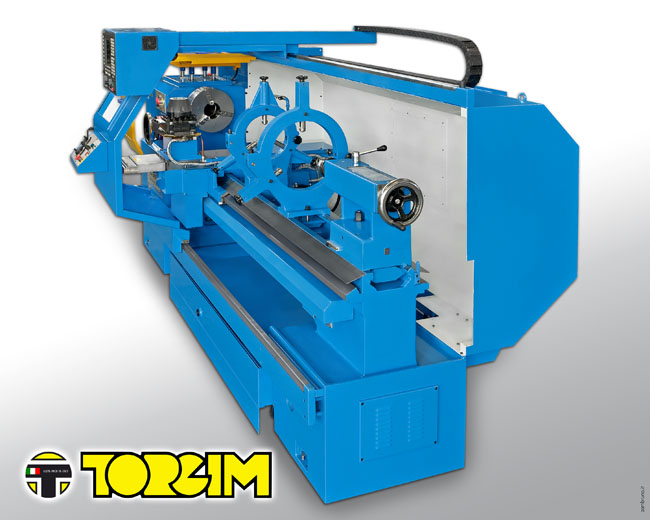

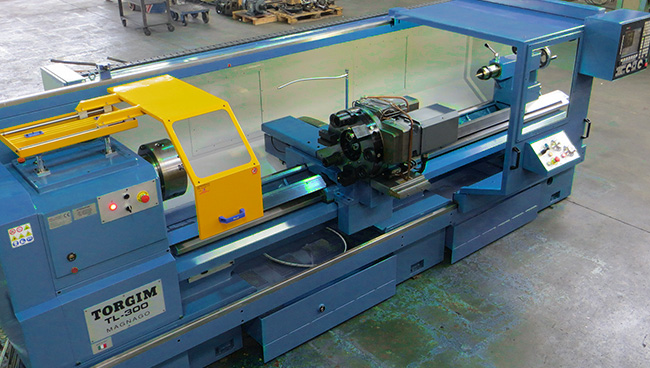

The teach-in lathes range is conceived to ease and optimize the work’s capacity of the traditional single pulley lathes operators in the machining of small and medial series of pieces

From the mechanical point of view the machine has all those shrewdnesses, derived by a fifty-year-old experience in the sector, that guarantee sturdiness, precision and reliability in the time.

Head: The head, with hole Ø 111 mm, is melted in special Meehanite stabilized cast-iron, steadily fixed on the bed and it is free from vibrations. All the gears, in steel Cr.Ni.Mo, hardened and ground, are mounted on high precision bearings. The spindle is supported in three points and is mounted on precision TIMKEN ball bearings. The speed gear range (2 ranges with continuos change) is mechanical so as to enable high working torques and it can be manual or automatic by means of an hydraulic piston and relative unit.

Toolholder turret : The machine can be equipped, according to the customer requests, with manual turrets with rapid change, electromechanical ones with four positions or eight positions.

Bed: the bed is of the type covered on the whole length and of sturdy structure with stiffening ribs that assure an absolute undeformability. It is melted in special Meehanite cast-iron and the slide guides largely sized, induction hardened and carefully ground maintain an absolute precision to the surface. Very useful is the natural gap under head allowing to work flanges, usually workable on bigger machines with less manoeuvrability.

Extra accessories: continuous “C ” axis, automatic turret 4/8 positions, VDI 40 driven tools, toolholder with internal cooling, tailstock with automatic sliding sleeve, automatic hydraulic or pneumatic self-centering chuck, swarf conveyor, unloading pieces unit.

Data:

- Spindle power 15 kW

- Height of centres 280/300 mm

- Turning diametre on carriage 390 mm

- Spindle bore 111 mm