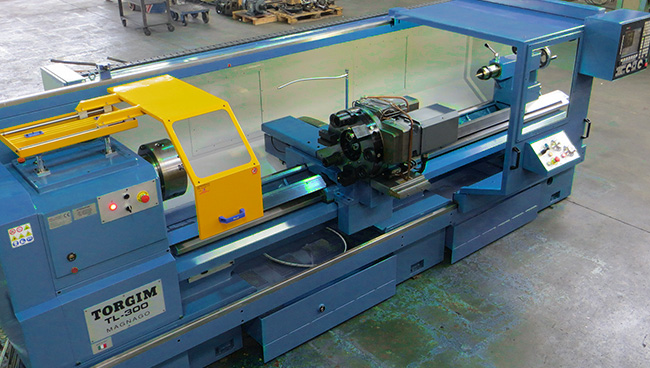

The machine TORGIM MBT300 allows to unload finished pieces with maximum Ø 105 mm and length 300 mm starting from the rough bar. To reach these results we have used the most modern productive technologies trying to reduce to the minimum the set-up times: “C” axis, rapid motion X/Z axis 10 m/min, 8 station turret with horizontal axis and rotating tools, toolholders with internal cooling, bars loader, tailstock with hydraulic sleeve, pneumatic self-centering chuck, swarfs conveyor and finished pieces unload unit.

The particular structural stiffness of the head-bed ensemble, typical of all our machines, has enabled the reaching of very high precision, repeatability and very short cycle time.

Data:

- spindle bore 105 mm

- height of centres 300 mm

- head with C continous axis

- turning diameter 400 mm