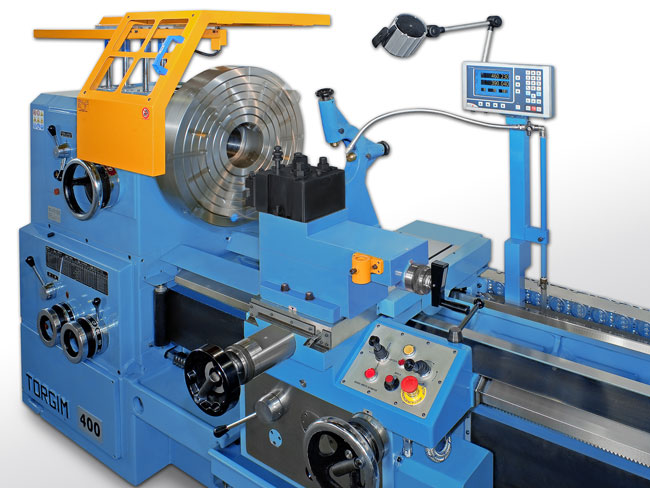

TORGIM 350/400CC is a series of modern machines characterized by the use of A.C. brushless motor and electromagnetic clutches in the apron that permit to eliminate the feed inserction levers obtaining a perfect operative functionality and in such a way simplifying the operator movements.

The pushbutton board, placed on the right side of the carriage, allows easy operation of the machine and gives to the operator full control over the main movements of the machine. The control devices are the following: Joystick for spindle rotations in both directions – Joystick for on/off feeds and rapid movements in all the directions of carriage and transversal slide – Luminous push button to release automatic longitudinal stop – Safety stop push button – Selector to drive small pulsing rotations of the spindle

The constant cutting speed lathe head, melted in special stabilized Meehanite cast-iron, gets the motion by an A.C. brushless motor that enables, through the references of the optical ruler of the X axis and a simple digital readout, to change the spindle rpm according to the diameter of the piece in working. So we get a constant cutting speed, modifiable in every time utilizing a potentiometer with instantaneous regulation. The surface finishing, especially in facing operations, is very nice.

The speed gear range (2 ranges with continuos change) is mechanical, the spindle hole is very wide (133 mm ).

The bed is covered on the whole length and has sturdy structure with stiffening ribs that assure an absolute undeformability. It is melted in special cast-iron Meehanite, it is distensioned in bracket, and its slide guides are largely sized, induction hardened and carefully ground in such a way as to maintain an absolute precision to the surface. Very useful is the natural gap allowing to work very large pieces typical of bigger machines which are less maneageble.

Data:

- spindle bore 133mm

- spidle motor 15 kW

- 2 gears with constant power

- turning diameter on carriage up to 600mm